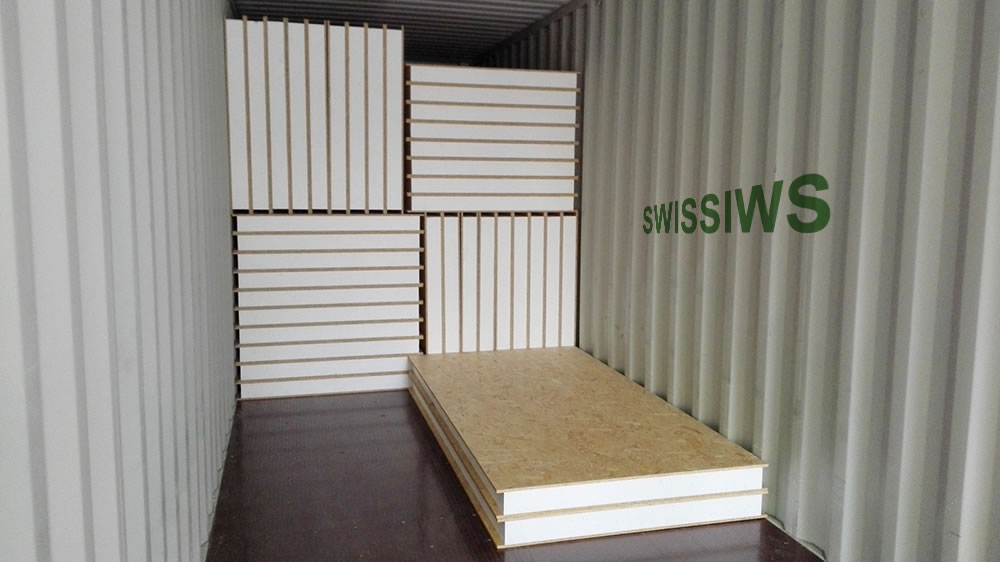

SWISSIWS OSB EPS SIP

OSB EPS SIPs are being applied in traditional construction method nearly 75 years ago. The first foam core SIPs were created in 1952.

Frank Lloyd Wright was exceptionally innovative and explored the idea of SIPs to incorporate beauty and simplicity into cost-effective homes.

Alden B. Dow, an architecture student of Frank Lloyd Wright, experimented further with the concept of structural panels. He had concerns about energy efficiency and was fearful over depleting natural recourses. Thus he sought to create a structural panel with an insulated core and is generally credited with creating the first structural insulated panel.

The chart below states general technical parameter of SWISSIWS OSB EPS SIP

| Sizes (mm) | 1220*2440 |

| Thickness of SIPs | 12/90/12, 12/100/12, 12/120/12 etc. |

| Thickness of OSB board | 9, 12, 15, 18 |

| Thickness of EPS | 50mm to 300mm |

| Density of EPS | 18kgs/m3 to 30kgs/m3 |

| Color of EPS | White, dark grey |

| Fireproof level | B1 |

| Edge treatment | T& G, four sides recessed, customized etc. |

| Top Layer | OSB board |

| Middle Core | EPS board |

| Bottom Layer | OSB board |

Advantages of SWISSIWS OSB EPS SIP

-Faster to build than most building methods.

-Factory prebuilt, resulting in cost reduction and speed of building.

-Superior insulation values compared to wood framing with fiberglass insulation.

-Superior weather performance.

-Superior structural performance compared to wood framing.

-Superior environmental performance through less waste generated by SIPs building and less HVAC needs from superior insulation.

-Proven performance in extreme conditions, documented observations show that SIP buildings withstood earthquakes in Japan, and storms/tornadoes in the US better than framed buildings.

-Reduction of need for skilled laborers.

-Reduction in the need of high-quality raw materials. Engineered wood production does not need high quality lumber.

-Tighter tolerances in building due to it being an engineered product.

-Tight control of material usage.